Research Overview

Research in our lab has both science and engineering, with focuses on:

Specific research interests are listed below.

- Integrated Computational Materials Engineering (ICME) modeling.

- Developing new materials or manufacturing methods using ICME-based design and experimental validation.

- Additive Manufacturing (AM).

- High-throughput experiments and modeling for materials informatics.

Specific research interests are listed below.

ICME Modeling in Additive Manufacturing (AM)

Develop ICME models to link materials' process-structure-property relations using Calphad-based microstructural models and physical-based property models.

- Development of Calphad-based models to predict Ni-based superalloy's microstructural evolution during AM.

- Prediction of materials' properties.

- Optimization of process (printing and post-printing) routines via ICME approach.

Develop ICME models to link materials' process-structure-property relations using Calphad-based microstructural models and physical-based property models.

- Additive Friction Stir Deposition (AFSD) repair for Al-alloys

Materials Development

High strength high conductivity (HSHC) alloys (Cu or Al) with heat resistance, for cable and conductor applications. Research directions include:

- ICME modeling to identify second phase particles in Al or Cu to increase strength and thermal stability without significantly reducing electrical conductivity.

- Rapid solidification prototyping to enable desired microstructure with finely dispersed coherent precipitates.

- New applications.

Ceramic-metal (Cermet) composite with high temperature strength, high fracture toughness and good chemical inertness, for applications in:

- Tool pin materials for friction stir welding on steels, Ni-based superalloys and Ti-alloys (>1000°C).

- Tool materials for metal cutting (> 800°C).

- Materials for extreme environment applications, such as cold-spray nuzzle.

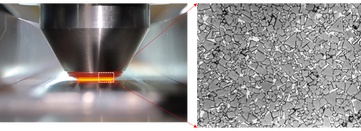

Nanocrystalline(NC) coating on steel engines to improve durability and wear resistance against high-pressure fuels such as F-24. Research directions include:

- ICME-based design of stable nanocrystalline alloys, acting as a catalyst for F-24 fuel.

- PVD or electrodeposition of NC coating on steel substrate or complex surface.

- Tribology behavior of NC coating against fuel flux under pressure.

Materials Informatics

Combine high-throughput experiments and computational approaches for materials database and model developments. Current research areas include:

- Forward-simulation analysis approach to efficiently extract interdiffusion and impurity diffusion coefficients for various systems.

- Dual-annealing to investigate phase transformation, precipitation evolution and interfacial energy, combined with modeling.

- ICME model development and validation with high-throughput experiments.

- Compositional dependent materials properties study.